- Home

- Products

- Vision Inspection Machine

- On Line Vision Inspection Machine

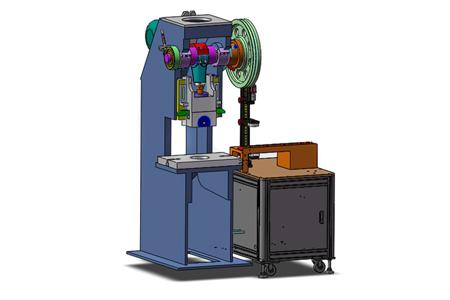

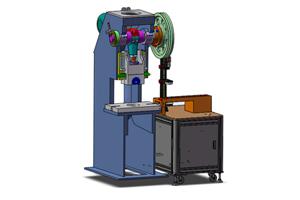

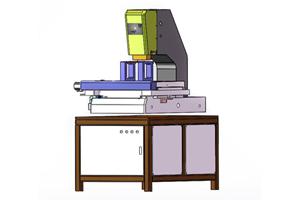

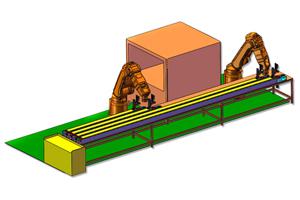

On Line Vision Inspection Machine

This product has been discontinued and removed from our shelves.

Machine vision inspection devices take advantage of machine vision products (i.e. image acquisition devices, including CMOS and CCD), and convert the features of the acquired objects into a picture signal, then transmits that signal to a specialized image processing system. According to the pixel distribution, brightness, color, and other specific information, the picture signal is then converted into a digital signal. After a number of different operations, the imaging processing system will then extract the required features, and control equipment actions according to differentiation results, which makes machine vision technology widely applicable for production line inspection processes. RKE’s on-line vision inspection equipment features an outstanding performance at competitive pricing.

- No need for manual contact measurement, preventing damage during inspection.

- Wide optical spectral response range of visual inspection.

- 24-hour continuous work, strong stability and increased inspection efficiency.

- Applicable inspecting products: fasteners, hardware accessories, stamping parts, die castings, plastic parts, etc.

- Inspection items: unqualified size, surface defect, etc.

- Inspection speed: depend on realistic production line speeds

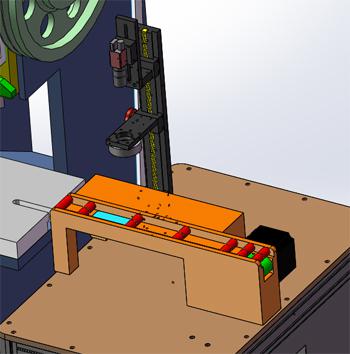

- Inspection width: depend on realistic production line width

- Inspection accuracy: ±0.02 mm (depend on the camera configuration)

- Available functions: sound-light alarm, unqualified products classification, halting response

- Inspection capabilities: surface inspection (front lighting), size inspection ( back lighting)