Optical sorting machine with U shaped slot

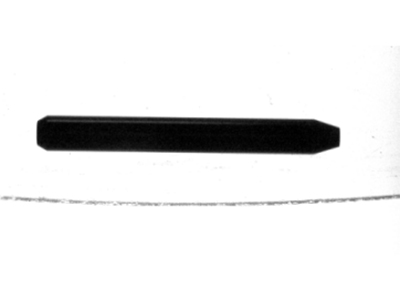

Pins, shafts, rollers and special components

±0.01mm

This machine is equipped with a vertical top view CCD camera for inspecting the multi-segment height, outer diameter, and total length of the product. It can be outfitted with additional CCD cameras for the inspection of leaks and other factors.

CCD1, head-up

CCD1, head-up head-up

head-upCustomized service can be provided according to the detect demand.

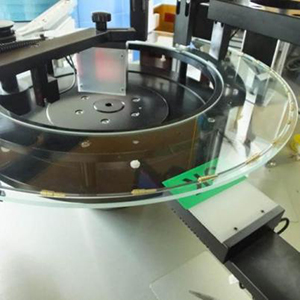

A patented U-shaped groove is added to the outer edge of the glass plate so that products can lay in the groove for inspection. Both products which can and cannot stand can be inspected by this machine.

The special track ensures products are correctly conveyed to the U-shaped groove on the glass platform. It is designed for products including shafts, guide pins, and pins.

The pre-set inspection parameters can be applied to new orders as needed. The inspection parameters of various products can be loaded quickly and conveniently.

RKE specializes in the production of vision sorting and inspection machines. Such advanced machine vision systems are technologically designed to provide automated solutions for quality control including sorting and inspection technologies for various parts and components.

Using a visual inspection machine for bolts significantly improves efficiency by accurately detecting defects, inconsistencies, and foreign materials. This automated process ensures high-quality sorting while reducing the need for manual labor, ultimately leading to more consistent quality control and faster sorting times.

Yes, our automatic inspection machines are designed with adjustable settings and customizable machine vision system, facilitating them to sort and handle a wide range of bolt types and sizes. This flexibility makes them suitable for various industrial applications, accommodating different shapes, sizes, and materials.

Please fill the form and we will be in touch with you as soon as possible.

To ensure the quality of products, manufacturing companies utilize a wide range of inspection techniques. Here at Dongguan RKE Intelligent Technology Co. we specialize in the design and production of optical vision (non-contact) automatic inspection equipment, allowing users to perform more effective quality control over their products.