Glass plate optical sorting machine

O-rings, rubber products and similar parts

±0.01mm

Automatic O-Ring Inspection Machine

Precision Automatic O-Ring Sorting Machine

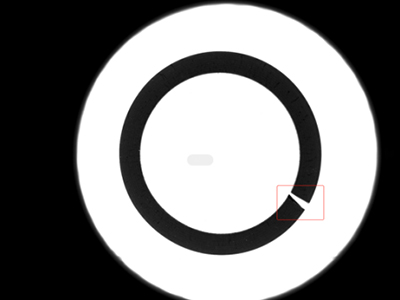

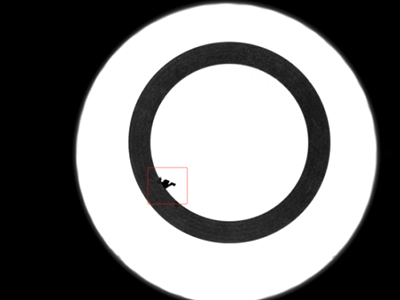

This inspection machine comes equipped with two high-precision industrial CCD cameras. The CCD1 is a head-up camera used for inspecting the thickness of products. The CCD2 is a vertical top view camera used for inspecting the inner diameter, outer diameter, and other parameters of each product. The CCD3 is a vertical top view camera used for inspecting for any appearance defects such as burrs and missing material.

Fracture

Fracture Burr

Burr Perforation

PerforationCustomized service can be provided according to the detect demand.

This machine can inspect various products. You only need to change the vibration plate or track. The preparatory work for inspecting a different type of product only requires about 30 minutes depending on the skill level of the operator.

Inspection software supports multiple languages, including Chinese, English, Japanese (Some functions still use Chinese language).

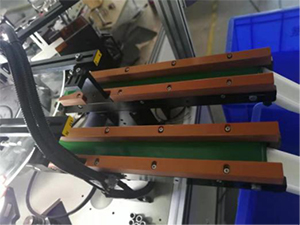

Due to some products that are difficult to move and easily stick to surfaces, a standard outlet may not be suitable for the blanking of the products. This machine uses a conveyor belt to transfer the products to ensure effective blanking.

Our automated vision sorting machines can inspect various types of parts, including bolts, screws, and nuts. They are also capable of inspecting various brass parts, pins, and precision turned components with the help of machine vision technology for quality assurance and reliable results.

The speed of the optical sorting machine varies depending on the type, size, and specific application of the parts being inspected. Our vision sorting machines can perform between 300 to 1,200 inspections per minute, ensuring high efficiency in quality control.

The accuracy of the vision sorting machine varies with the characteristics of the part, such as size and color. Our visual inspection systems can achieve a precision of up to 0.01 mm, providing highly reliable inspection results.

Please fill the form and we will be in touch with you as soon as possible.

To ensure the quality of products, manufacturing companies utilize a wide range of inspection techniques. Here at Dongguan RKE Intelligent Technology Co. we specialize in the design and production of optical vision (non-contact) automatic inspection equipment, allowing users to perform more effective quality control over their products.