Customized service can be provided according to the detect demand.

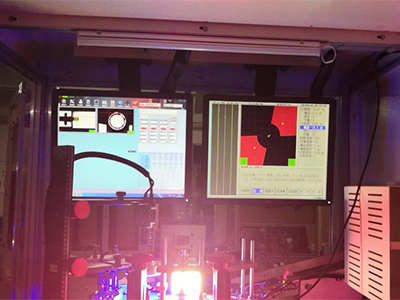

This machine uses a stationary device to prevent the swinging of products caused by the rotary indexing table. The contact type pressing device on the workstations keep the product stationary so the head up camera can take accurate photos to ensure high precision.

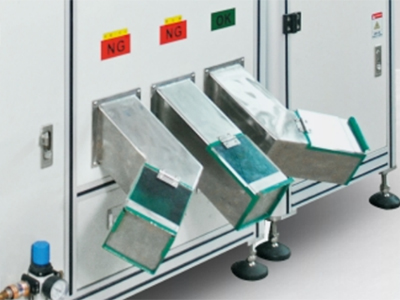

Heat treatment defective products have a special outlet so they will not be mixed with dimension defective products.

It avoids unnecessary dimension inspection for heat treatment defective products.

It can be equipped with an eddy current probe for inspecting products for the presence of heat treatment.

Our automated vision sorting machines can inspect various types of parts, including bolts, screws, and nuts. They are also capable of inspecting various brass parts, pins, and precision turned components with the help of machine vision technology for quality assurance and reliable results.

The speed of the optical sorting machine varies depending on the type, size, and specific application of the parts being inspected. Our vision sorting machines can perform between 300 to 1,200 inspections per minute, ensuring high efficiency in quality control.

The accuracy of the vision sorting machine varies with the characteristics of the part, such as size and color. Our visual inspection systems can achieve a precision of up to 0.01 mm, providing highly reliable inspection results.

Please fill the form and we will be in touch with you as soon as possible.