- Home

- Products

- Vision Inspection Machine

- Robotic Vision Inspection System

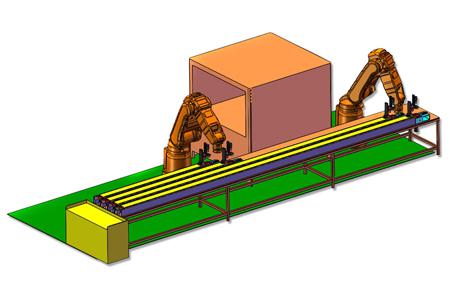

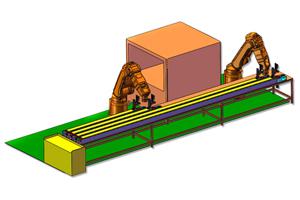

Robotic Vision Inspection System

This product has been discontinued and removed from our shelves.

The robotic vision inspection system can be customized according to individual customer requirements. During production processes, it is often unavoidable that there will be unqualified or defect appearing products, which heavily influence product quality. Because it is often difficult to quickly and accurately manually detect these unqualified products, and a conventional robot can only pick out items along a fixed, programmed in advance route, a vision system is an ideal solution. The vision system will recognize and locate defective products, then the robot can remove these products, no matter where on the production line they are.

If you combine RKE’s robotic vision inspection system with your robots, you can precisely and quickly inspect and detect any size and surface problems during the production process. Our robotic vision inspection systems, featuring a higher accuracy, stronger stability and better durability over others available on the market, will assist customers in reducing production costs, improve product quality, and increase production efficiency.

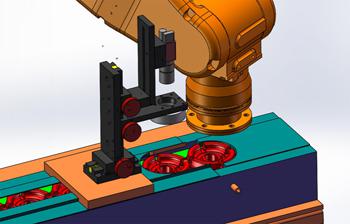

Parameters- Applicable inspecting products: fasteners, hardware accessories, stamping parts, die castings, plastic parts, etc.

- Inspection items: unqualified size, surface defect, etc.

- Inspection speed: depend on realistic production line speed

- Inspection width: depend on realistic production line width

- Inspection accuracy: ±0.02 mm (depend on the camera configuration)

- Available functions: sound-light alarm, unqualified products classification, halting response

- Inspection capabilities: surface inspection (front lighting), size inspection ( back lighting)