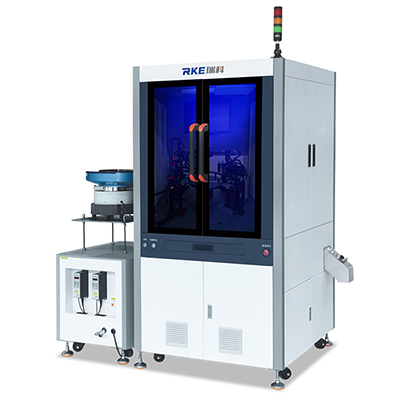

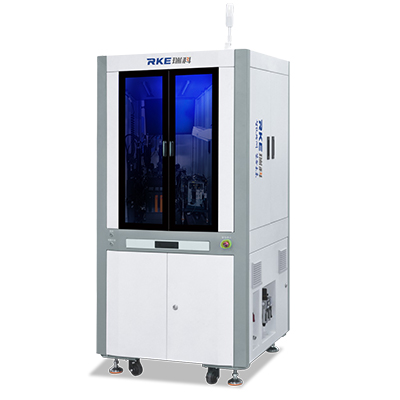

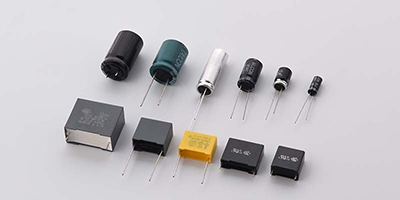

RKE offers a comprehensive range of sorting machines, including optical inspection and sorting machine, rotary indexing dial optical sorting machine, headed fastener optical sorting machine. These products utilize advanced optical image recognition technologies, combined with high-precision industrial cameras, lenses, and sophisticated software, to meet the needs of various industries and applications delivering extraordinary accuracy and efficiency. Our optical inspection and sorting machines are widely used domestically and internationally for various industrial needs such as manufacturing, medical, electronics, automotive, and many other sectors.

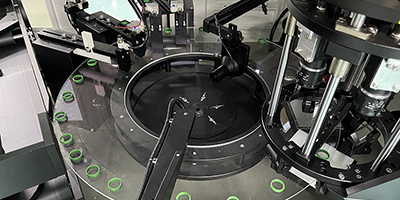

Optical inspection machine for vision sorting and inspection of parts including screws, nuts and washers

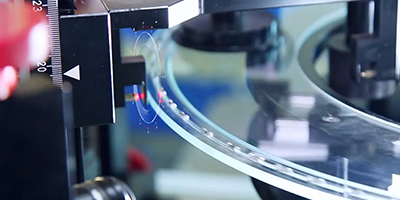

Optical inspection machine for vision sorting and inspection of cylindrical parts

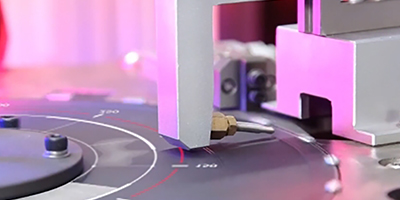

Optical inspection machine with slotted indexing dial for sorting headed fasteners

Optical inspection machine with Eddy current system for inspecting hardness and separating non-ferrous metal

Artificial intelligence-based inspection machine for internal and external defect detection

Artificial intelligence-based inspection machine for inspecting six sides at once

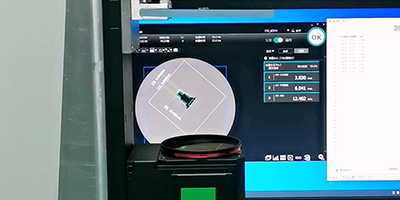

The one-button measuring instrument, developed by our company, is a versatile and highly precise tool for measuring a wide range of products such as screws, nuts, washers, mobile phone parts, hardware components, and uniquely shaped items. It effortlessly measures geometric dimensions including outer diameter, width, height, and length.

Vision inspection machine combined with product packaging

RKE specializes in the production of vision sorting and inspection machines. Such advanced machine vision systems are technologically designed to provide automated solutions for quality control including sorting and inspection technologies for various parts and components.

Our automated vision sorting machines can inspect various types of parts, including bolts, screws, and nuts. They are also capable of inspecting various brass parts, pins, and precision turned components with the help of machine vision technology for quality assurance and reliable results.

The speed of the optical sorting machine varies depending on the type, size, and specific application of the parts being inspected. Our vision sorting machines can perform between 300 to 1,200 inspections per minute, ensuring high efficiency in quality control.

The accuracy of the vision sorting machine varies with the characteristics of the part, such as size and color. Our visual inspection systems can achieve a precision of up to 0.01 mm, providing highly reliable inspection results.

For More Information Contact Us Now!

+86-18938290376