Optical sorting machine with rotary slotted metal disk

Bolts, screws, spindles, threaded pins and more

±0.02mm

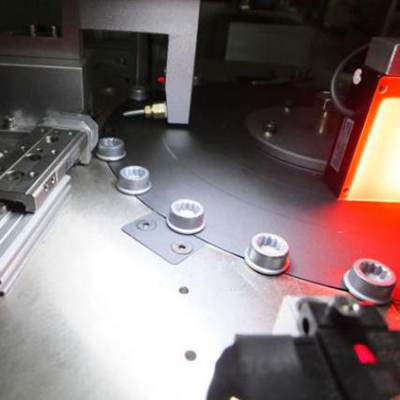

This inspection equipment is outfitted with four industrial CCD cameras. The CCD1 is a head-up camera used for inspecting the multi-segment height and outer diameter of the product. The CCD2 is a vertical bottom view camera used for inspecting the aperture and the burr of the product. The CCD3 is a vertical top view camera used for inspecting the opposite diagonal and angle of the product. It is also used to detect for chamfering. The CCD4 is a 45° tilt camera used to determine if the product has internal threads.

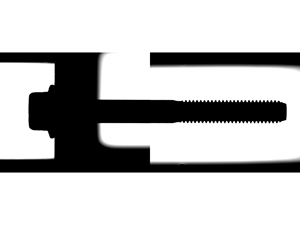

CCD1, head-up

CCD1, head-up CCD2, vertical bottom view

CCD2, vertical bottom viewCustomized service can be provided according to the detect demand.

This machine features a solenoid operated blow-off to blank NG products.

It has optical fiber sensing device behind the NG expel workstation to prevent NG products from being carried to the OK outlet.

If it detects the NG product is not blanked, the machine will be automatically stopped by the control software.

This machine uses a solenoid operated blow-off which is high speed and contactless, protecting the products from damage the products.

The compressed air is processed by the dryer equipped with fine micro filters.

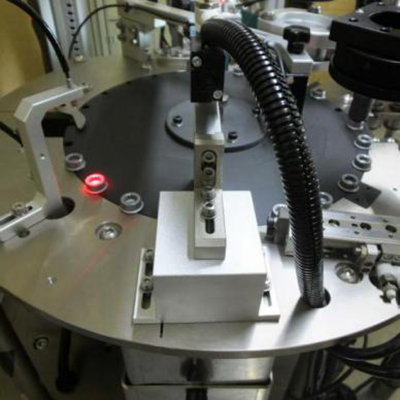

The products are conveyed via a vibration plate to the rotary indexing table.

There are equidistant slots on the rotary indexing table which will pass the workstations of various cameras in turn to inspect related parameters.

Products of different rod diameters require different rotary indexing tables.

Yes, our automatic inspection machines are designed with adjustable settings and customizable machine vision system, facilitating them to sort and handle a wide range of bolt types and sizes. This flexibility makes them suitable for various industrial applications, accommodating different shapes, sizes, and materials.

Absolutely. Our visual sorting machines can sort objects based on multiple criteria at the same time, including color, shape, size, and texture. This multi-criteria sorting capability enhances accuracy and versatility, making it easier to meet specific quality standards for different products.

No, visual sorting machines are designed with automated feeding systems, minimizing the need for manual intervention. This automation increases quality, efficiency and consistency, as parts are fed into the machine seamlessly for inspection and sorting.

Please fill the form and we will be in touch with you as soon as possible.

To ensure the quality of products, manufacturing companies utilize a wide range of inspection techniques. Here at Dongguan RKE Intelligent Technology Co. we specialize in the design and production of optical vision (non-contact) automatic inspection equipment, allowing users to perform more effective quality control over their products.