The glass dial optical sorting machine is an automated device designed for vision sorting and inspection of parts, including screws, nuts, and washers. Utilizing a highly transparent glass dial, this machine ensures that parts are stably placed, laid flat or standing, and can be thoroughly inspected from multiple angles.

An additional camera can be installed underneath the glass dial to inspect objects requiring double-sided inspection, provided they are free from oil residues, providing a comprehensive analysis of each item, ensuring defects are accurately identified. The system captures images of the items and uses industrial-grade computers along with proprietary software to analyze the image, dimensions and appearance of the parts. This setup enables cost-effective and efficient automated inspection and testing operations, enhancing the overall quality and reliability of the output.

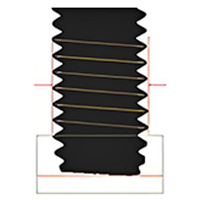

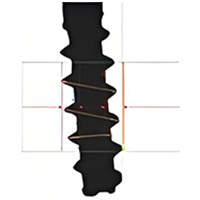

Precision Screw Visual Sorting Machine

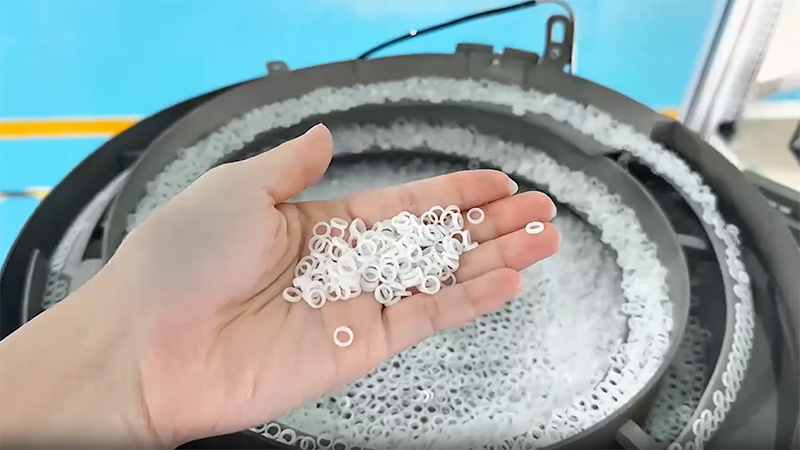

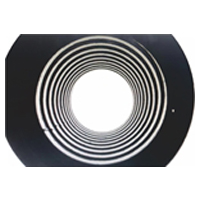

Rubber Ring Visual Sorting Machine

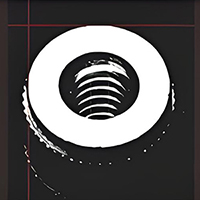

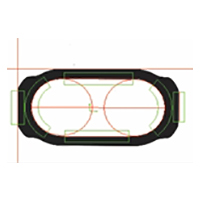

Fastener Inspection

Mobile accessories inspection

Rubber products inspection

Electronic component inspection

Special hardware inspection

Shaft components

The glass dial optical sorting machine boasts high precision in its inspection capabilities, achieving an accuracy of up to 0.01 mm. This allows the machine to accurately determine whether products meet quality standards, making it ideal for industries where even minor defects can significantly impact product performance and safety.

The operation speed of the glass dial sorting machine can reach 300 to 1200 inspections per minute, efficiently handling large volumes of products. This high throughput enhances productivity and reduces the need for manual labor. The high-speed operation is essential for industries with demanding production schedules, ensuring a seamless and continuous flow of quality-controlled products.

The optical sorting system offers versatile configuration options, allowing adjustments of various parameters, such as lighting conditions and image processing algorithms. It supports additional hardware like cameras and lasers, making it adaptable to various product types and inspection needs with optimal performance.

Beyond basic sorting, the optical sorting machine can detect surface defects, measure dimensions, and classify products based on color and shape. This multifunctionality enables comprehensive quality control, reducing the chances of defective products reaching the market.

An intuitive human-machine interface (HMI) is featured in the sorting machine, which simplifies operation and allows operators to easily monitor and adjust the equipment’s settings. This user-friendly setup minimizes operator training time and reduces the likelihood of operational errors, enhancing overall efficiency and safety.

Yes, our automatic visual aborting and inspection machines can be integrated into existing production lines as they are often designed with adaptability in mind, featuring customizable settings and interfaces to align with various production environments. This integration helps manufacturers enhance their quality control processes without needing to overhaul their current production setups.

Visual sorting machines are known for their high levels of accuracy, often exceeding 95%. The precision depends on factors like the part's characteristics, the inspection criteria, and the machine’s technology. Advanced optical systems can detect minute defects, inconsistencies, and deviations, ensuring that only components meeting stringent quality standards are approved.

Using visual inspection machines for washers and nuts ensures uniformity and consistent quality in production. These machines can quickly detect defects, such as surface cracks, size deviations, and incorrect shapes, which are critical in components like washers and nuts. By automating the inspection process, manufacturers can reduce manual labor, improve product reliability, reduce wastage, and enhance production efficiency.

Please fill the form and we will be in touch with you as soon as possible.