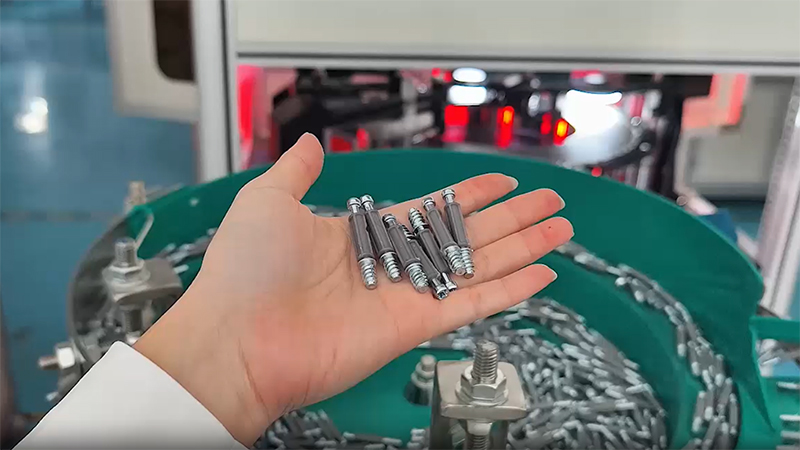

The rotary indexing dial optical sorting machine is designed for the precise inspection and sorting of components using a slotted indexing dial, which allows parts to be stably positioned for inspection of both dimensions and surface characteristics. It is particularly suitable for items that cannot stand upright securely. The sorting machine can inspect components with lengths ranging from 10 to 80 mm. It operates at a speed of 300 to 1200 pieces per minute, with an accuracy of ±0.02 mm, ensuring precise detection of defects and dimensional variances, making it ideal for high-volume production lines.

The rotary indexing dial optical sorting machine integrates several systems to perform thorough inspection and sorting of cylindrical components. It includes an automated feeding system, a transmission and positioning, an automatic measurement system uses advanced sensors and cameras to evaluate dimensions and surface features, determining the quality of each component. The automated sorting and unloading system separate acceptable products from defective ones, directing them accordingly. An intelligent control system oversees the entire process, allowing real-time adjustments to inspection criteria based on user settings. Additionally, a computer data processing system collects and analyzes measurement data, providing statistical insights for quality control and optimization.

All the integrated functionality ensures efficient, accurate, and reliable inspection and sorting, making the machine suitable for high-volume production environments.

Rotary Bolt Optical Sorting Equipment

Rotary Fastener Optical Sorting Equipment

Fastener chamfer and crush detection

Special hardware inspection

Shaft inspection

Using a visual inspection machine for bolts significantly improves efficiency by accurately detecting defects, inconsistencies, and foreign materials. This automated process ensures high-quality sorting while reducing the need for manual labor, ultimately leading to more consistent quality control and faster sorting times.

No, visual sorting machines are designed with automated feeding systems, minimizing the need for manual intervention. This automation increases quality, efficiency and consistency, as parts are fed into the machine seamlessly for inspection and sorting.

A visual sorting and inspection machine may require an external air compressor, especially for sorting tasks that involve air jets. The necessity of a compressor depends on the machine's design and the specific application it is used for.

Please fill the form and we will be in touch with you as soon as possible.