Our optical inspection machines are widely used in the assembly and quality control processes of the electronics manufacturing industry. It is engineered to eliminate production defects, verify PCB assembly accuracy, and enhance supply chain traceability, particularly effective for inspecting solder quality on circuit boards, verifying component placement, and controlling print quality. By integrating image recognition technology with high-speed automation, our systems provide high precision and efficiency in inspecting electronic components.

Our optical sorting and inspection systems are designed to meet the rigorous demands of the electronics industry, providing reliable solutions for manufacturers to maintain high-quality standards and streamline their production processes.

Mobile Button Visual Inspection Equipment

Precision Gear Visual Inspection Equipment

Precision Parts Testing Equipment

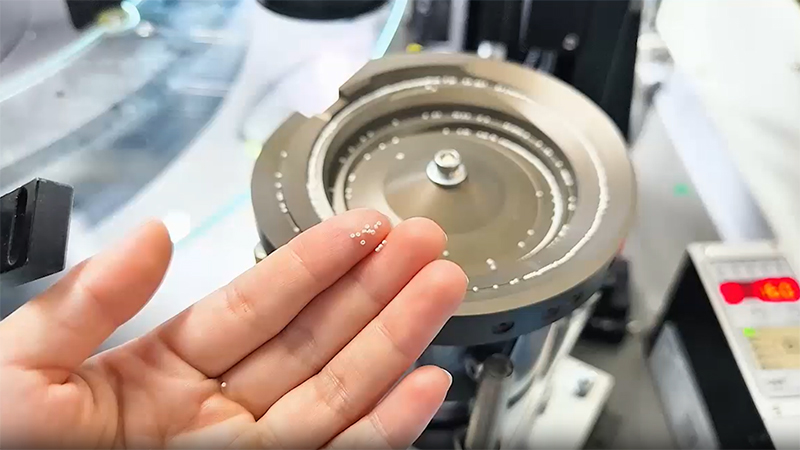

Capacitor testing equipment is composed of a glass plate inspection device and rotary indexing table.

Features

RKE specializes in the production of vision sorting and inspection machines. Such advanced machine vision systems are technologically designed to provide automated solutions for quality control including sorting and inspection technologies for various parts and components.

Our automated vision sorting machines can inspect various types of parts, including bolts, screws, and nuts. They are also capable of inspecting various brass parts, pins, and precision turned components with the help of machine vision technology for quality assurance and reliable results.

The speed of the optical sorting machine varies depending on the type, size, and specific application of the parts being inspected. Our vision sorting machines can perform between 300 to 1,200 inspections per minute, ensuring high efficiency in quality control.

Please fill the form and we will be in touch with you as soon as possible.