The six-sided visual inspection machine is an automated system designed for the comprehensive inspection of products like LEDs and semiconductor components. This machine operates at speeds ranging from 3000 to 12000 pieces per minute, ensuring high throughput for industrial applications.

The visual inspection machine utilizes advanced artificial intelligence and image processing technology to provide thorough inspections of all six sides of a product simultaneously. It is capable of detecting a wide range of defects, including residual glue, missing glue, excess glue, bubbles, impurities, surface blurring, wire misalignment, poor welding, aluminum foil defects, and aluminum foil whitening. Based on the analysis results, it classifies the products into acceptable and defective categories, ensuring precise quality control.

Multi-Sided Connector Visual Inspection Machine

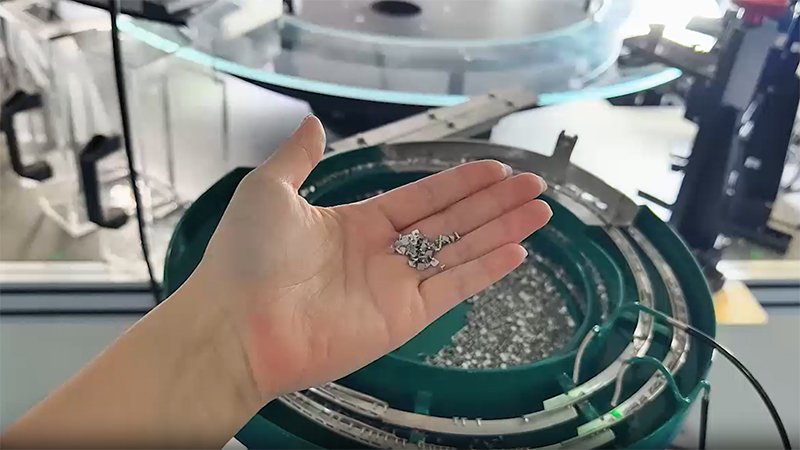

Multi-Sided Hardware Sorting Machine

Vision inspection systems powered by deep learning automate manufacturing operations by detecting defects, contaminants, functional issues, and other anomalies in products. These systems enhance the manual quality processes, improving overall business quality and reducing costs. Each test record is stored and used for self-learning, increasing detection accuracy over time through continuous improvement.

Most machine vision systems come with a software tool library designed to perform various types of inspections. These systems monitor the visual appearance of materials through statistical analysis, automatically identifying potential defects on the material surface. Defects are classified based on contrast, texture, and/or geometric shape similarity, ensuring high inspection accuracy.

Vision inspection systems can perform a wide range of tasks to ensure product quality and integrity. They verify the correct placement of labels, confirm the integrity of medical product packaging by ensuring drug bottles are fully sealed and secured with tamper-evident seals, and inspect finished products for defects such as surface scratches, bent secondary diode pins, and incomplete welds. These systems also count items, such as pills in blister packs, bottles in boxes, and components in kits, and check characteristics of finished assemblies, such as the inclusion of consumer safety inserts and the completion of assembly operations. The vision inspection systems are also capable of measuring microscopic dimensions, such as the gap on spark plugs, ensuring precise and accurate measurements for quality control.

Please fill the form and we will be in touch with you as soon as possible.