Traditionally, inspecting the appearance and quality of fasteners involved manual visual inspection or using tools like calipers. This method is not only slow and imprecise but also highly dependent on the worker’s subjective judgment and alertness. These limitations often lead to misjudgments and missed defects, often inadequate for modern production requirements.

By incorporating machine vision inspection systems, manufacturers can significantly enhance the precision and speed of fastener inspection processes. These systems offer high accuracy and rapid detection capabilities, substantially improving production efficiency and the quality of outgoing products. It overcomes the limitations of traditional inspection methods, offering consistent and objective evaluations that are not influenced by human factors.

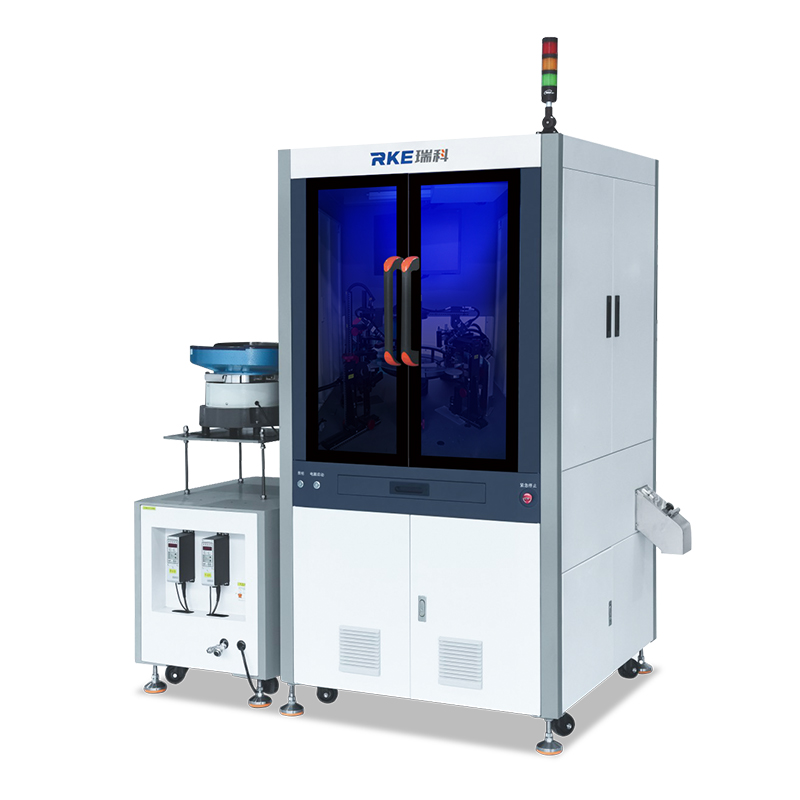

Connector Defect Optical Sorting Machine

Plug Defect Visual Inspection Machine

Connector Defect Visual Inspection Machine

Connector Optical Sorting Machine

Thanks to advancements in technology, industry today is becoming more and more automated, allowing us to not only produce more products but also products of superior quality. The threaded pin is an indispensable component used in all sorts of mechanical equipment. If the threaded pin has a defect, it can directly impact the performance of the equipment in which it is installed. Therefore, clients have emphasized the importance of the quality of threaded pins and traditional manual inspection simply cannot satisfy these requirements. As a nondestructive inspection method, machine vision is an outstanding alternative to traditional manual inspection.

Our hardware vision inspection machines are designed for inspecting the dimensions of the different fasteners as well as for hole blockages, burrs, rough edges, and other parameters. Its inspection and sorting speed depends on the feeding system, up to 300-1200 pieces per minute.

Features

The CCD surface defect detection system is a new intelligent control system that utilizes digital image processing technology to realize automatic visual inspection of each product to replace traditional manual inspection methods. It inspects the edge contour of the product to find any surface defect with high inspection speed and accuracy.

Working principle

The detection system uses a special light source to project a clear image of the product on the background, then it analyzes the image to find any defects.

The service life of a spring is closely related to its quality. Therefore, strict surface quality inspection is necessary. Spring manufacturer use various methods to inspection the product so as to ensure stable product quality.

The test items of the springs include appearance, dimension, compliance, and more. Taking dimension inspection for example, some manufacturers use a vernier caliper to inspect the spring manually. This not only diminishes efficiency but can also be inaccurate. Some manufacturers have imported CCD visual inspection machines to inspect springs, minimizing labor costs and ensuring stable product quality and that’s not all. It also enables greater management and tracking capabilities.

CCD visual inspection machines can perform comprehensive inspection processes for springs, checking their dimensions, color, defects, and more. The equipment works in combination with a camera, light source, and special software. They can accurately detect various defects in springs including lateral deformation, vertical deformation, fractures, etc. They offer high inspection speed, accuracy, and reliable results.

The weld nut inspection equipment is composed of various systems:

Yes, our automatic visual aborting and inspection machines can be integrated into existing production lines as they are often designed with adaptability in mind, featuring customizable settings and interfaces to align with various production environments. This integration helps manufacturers enhance their quality control processes without needing to overhaul their current production setups.

Visual sorting machines are known for their high levels of accuracy, often exceeding 95%. The precision depends on factors like the part's characteristics, the inspection criteria, and the machine’s technology. Advanced optical systems can detect minute defects, inconsistencies, and deviations, ensuring that only components meeting stringent quality standards are approved.

Using visual inspection machines for washers and nuts ensures uniformity and consistent quality in production. These machines can quickly detect defects, such as surface cracks, size deviations, and incorrect shapes, which are critical in components like washers and nuts. By automating the inspection process, manufacturers can reduce manual labor, improve product reliability, reduce wastage, and enhance production efficiency.

Please fill the form and we will be in touch with you as soon as possible.