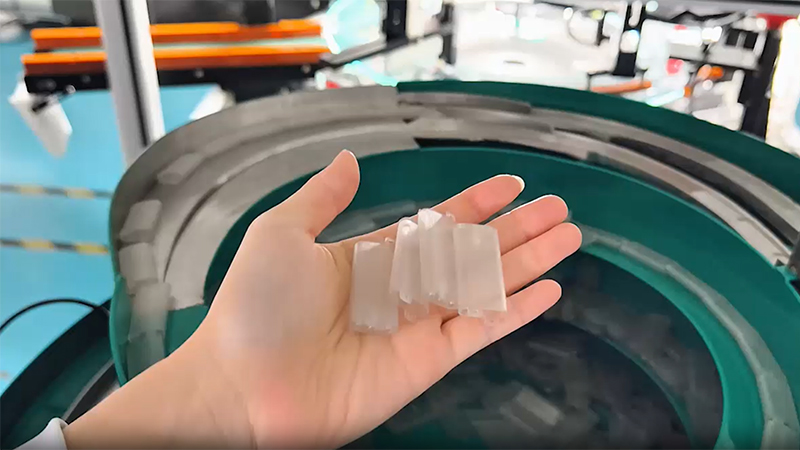

As industrial demand grows, rubber products are increasingly used in high-precision applications. Common components like rubber seals and rubber buttons are integral in various industries, but ensuring the quality of these parts poses unique challenges. However, traditional inspection methods, which often involve manual inspection, struggle to keep up with these demands due to the flexibility and dark coloration of rubber materials, making defects such as cracks, contamination, and material inconsistencies difficult to detect.

Our advanced optical vision inspection system offers a reliable solution to these challenges. By utilizing high-resolution industrial cameras, specialized lighting systems, and sophisticated image processing software, our system can accurately measure the dimensions of rubber parts, ensuring they meet design specifications. It also detects a wide range of defects, including deformation, incomplete molding, flash, material contamination, and poor surface finishes.

This automated approach not only improves the accuracy of quality control processes but also significantly enhances production efficiency and consistency. By eliminating the subjectivity and limitations of manual inspection, our vision system ensures that every part that leaves your production line meets high standards of quality, providing you with a competitive edge in the market.

Electronic Cigarette Visual Inspection Equipment

Medical Bottle Appearance Defect Inspection Machine

Bottle Cap Appearance Defect Inspection Equipment

Plastic Parts Appearance Defect Inspection Equipment

RKE specializes in the production of vision sorting and inspection machines. Such advanced machine vision systems are technologically designed to provide automated solutions for quality control including sorting and inspection technologies for various parts and components.

Our automated vision sorting machines can inspect various types of parts, including bolts, screws, and nuts. They are also capable of inspecting various brass parts, pins, and precision turned components with the help of machine vision technology for quality assurance and reliable results.

The speed of the optical sorting machine varies depending on the type, size, and specific application of the parts being inspected. Our vision sorting machines can perform between 300 to 1,200 inspections per minute, ensuring high efficiency in quality control.

Please fill the form and we will be in touch with you as soon as possible.