As mobile phone components become increasingly sophisticated, the demand for high-quality standards and large-scale production has risen. Traditional inspection methods, which rely on manual processes, are no longer sufficient to meet these modern demands. The application of vision inspection machines has become essential to ensure the highest quality and efficiency in the production of mobile phone parts.

Using AI-powered optical vision inspection equipment for mobile phone parts significantly enhances inspection efficiency and accuracy. This technology improves the quality of outgoing products, reduces quality control costs for manufacturers, and boosts market competitiveness.

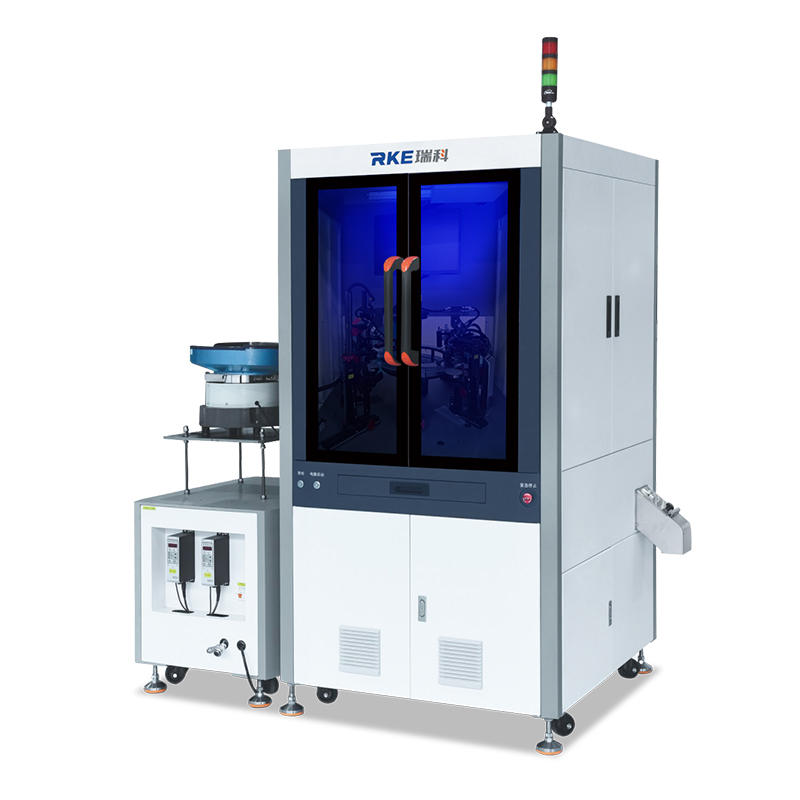

New Energy Battery Cover Visual Inspection Machine

Ceramic Ring Visual Inspection Machine

Capacitor Shell Visual Inspection Machine

The cover glass layer of smartphones is one of the most important design and functional components of the products and many manufacturers compete in this field. Therefore, the inspection of cover glass layer products plays a vital role in smartphone manufacturing. Many smartphone manufacturers still use manual detection methods which can cause low efficiency and an increase in missed defects, resulting in costs that can be difficult to overcome.

Following the completion of the various assembly processes, manufacturers will inspect the surfaces of the smartphones or tablets to find defects including scratches, gaps, dents, bulges, etc. They also inspect the screen by operating the screen to detect any defects such as bright spots, dark spots, and backlight failure.

The advantages of CCD visual inspection equipment in smartphone appearance inspection

A machine vision system consists of a series of components such as cameras, lenses, lighting, and image processing units, which are designed to automate the process of inspecting and analyzing objects by capturing and processing images. They are commonly used in manufacturing and quality control to ensure products meet specified standards. We can customize a machine vision system based on your application needs.

Machine vision products are widely used for appearance inspection. These systems employ vision cameras to examine products during manufacturing or quality control processes. The visual inspection system ensures that products are free from scratches, damages, missing parts, burrs, dents, discoloration, or any other visual defects. It is crucial in maintaining high standards of product quality and reliability in various industries.

Please fill the form and we will be in touch with you as soon as possible.